Product Description

Product Description

Agriculture Machinery Gear Box Agricultural Agri Farm Tractor Mower Bevel Digger Fertilizer Spreader Rotary Tiller Right Angle Pto Shaft Reducer Gearbox

The Agriculture Machinery Gear Box is a high-quality and durable gearbox designed for use in various agricultural applications. This gearbox is specifically engineered to meet the demands of agri-farm tractors, mowers, diggers, fertilizer spreaders, rotary tillers, and other agricultural machinery.

With its bevel gear design, this gearbox ensures smooth and efficient power transmission, allowing for optimal performance and productivity. The right angle PTO shaft reducer gearbox is built to withstand heavy-duty usage, making it ideal for demanding agricultural tasks.

Featuring a robust construction, this gearbox offers exceptional reliability and longevity, reducing the need for frequent maintenance and replacement. Its compact design allows for easy installation and integration into existing agricultural equipment.

Key Features:

- Bevel gear design for smooth power transmission

- Designed for agri-farm tractors, mowers, diggers, fertilizer spreaders, rotary tillers, and more

- Heavy-duty construction for durability

- Compact design for easy installation

Enhance the performance and efficiency of your agricultural machinery with the Agriculture Machinery Gear Box. Invest in this reliable and high-performing gearbox to maximize productivity and minimize downtime.

Product Parameters

| 1. Large output torque |

| 2. Safe, reliable, economical, and durable |

| 3. Stable transmission, quiet operation |

| 4. High modularization design, may equip with various outer power inputs conveniently. The same machine type may equip with various power motors. It is easy to realize the combination and junction between every machine type |

| 5. Form of installation: The position to be installed is not limited |

| 6. High strength, compact the box body of high strength cast iron, gear and gear shaft adopt the gas carbonization, quenching, and fine grinding process, therefore the bearing capacity of unit volume is high |

| 7. Long life: Under the condition of the correct type chosen(including choosing suitable operation parament ) normal operation and maintenance, the life of the main parts speed reducer(except wearing parts)should not be less than 20000 hours |

| 8. Low noise: Because the main parts of the speed reducer are processed, and tested critically, therefore the noise of the |

Detailed Photos

Company Profile

United Metal Products (HangZhou) Co., Ltd. is located in west coast new economic district, HangZhou, China.

Our products exported to the United States, Canada, Brazil, Germany, France, Italy, Denmark, Australia etc for more than 16 years.

We have passed certification of ISO9000, ISO14001, TS16949. etc.

We focus on metal parts including casting parts and machining parts for construction machinery, agricultural machinery, auto parts, railway parts etc.

Machining casting parts, forging parts, aluminum die casting parts etc.

Bar machining parts, shaft etc.

Bolt/nut/washer.

Welding parts, sheet metal part, bending parts etc.

Fin-type radiators.

Our vast experience includes parts ranging from 0.01kg to 1000 kg with annual volumes from 500 up to 200, 000 pieces in industries such as:

Construction – Excavators, Articulating Dump Trucks, Graders, Pavers, Wheel Loaders, Skid Steers, Asphalt Compactors

Agriculture – Tractors, Combines, Sprayers, Seeders, Implement Attachments, Planters, Air Drills, Cultivators, Balers

Material Handling – Forklifts, Reach Trucks, Order Pickers

Aerial Platforms – Scissors Lifts, Telehandlers

Rail/Transportation – Freight Trains

Forestry – Feller Bunchers

Mining – Mining Trucks

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Marine, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Cycloidal |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Calculation of Reduction Ratio in a Cycloidal Gearbox

The reduction ratio in a cycloidal gearbox can be calculated using the following formula:

Reduction Ratio = (Number of Input Pins + Number of Output Pins) / Number of Output Pins

In a cycloidal gearbox, the input pins engage with the lobes of the cam disc, while the output pins are engaged with the cycloidal pins of the output rotor. The reduction ratio determines the relationship between the number of input and output pins engaged at any given time.

For example, if a cycloidal gearbox has 7 input pins and 14 output pins engaged, the reduction ratio would be:

Reduction Ratio = (7 + 14) / 14 = 1.5

This means that for every 1 revolution of the input pins, the output rotor will complete 1.5 revolutions. The reduction ratio is a key parameter that influences the output speed and torque of the cycloidal gearbox.

Patents Associated with Cycloidal Gearbox Designs

Throughout the history of cycloidal gearbox development, several patents have been filed for various designs and applications. Some notable patents include:

- Harmonic Drive: Ralph B. Heath’s patent for the “Harmonic Drive” (US Patent 2,906,143), filed in 1957, is one of the most famous patents related to cycloidal gear systems. This patent introduced the concept of a high-precision reduction gear mechanism using flexible components.

- Cycloidal Drive Mechanism: A patent by James Watt for a “Cycloidal Drive Mechanism” (GB Patent 1812), dating back to the 18th century, is often cited as one of the early references to cycloidal motion and gears.

- Planetary Roller Transmission: US Patent 3,671,927 by C.F. Kafesjian and H. Blumenstock introduced a “Planetary Roller Transmission” in 1972, describing a cycloidal drive mechanism with planetary motion.

- Cycloidal Speed Reducer: A patent for a “Cycloidal Speed Reducer” (US Patent 5,588,583) was granted to Richard J. Pieprzak in 1996, focusing on an improved design of cycloidal gears for various applications.

These patents represent a small sample of the numerous innovations and designs related to cycloidal gear systems that have been patented over the years. Patents play a significant role in protecting and promoting innovation in the field of gearbox technology.

Advantages of Using a Cycloidal Gearbox

Cycloidal gearboxes offer several advantages that make them well-suited for various applications:

- High Torque Density: Cycloidal gearboxes provide a high torque output relative to their size and weight. This makes them ideal for applications where space is limited, and high torque is required.

- Compact Design: The unique arrangement of cycloidal pins and lobed profiles results in a compact gearbox design. This is advantageous when dealing with constrained installation spaces.

- Smooth and Precise Motion: Cycloidal motion generates smooth and controlled movement, making these gearboxes suitable for applications requiring accurate positioning, such as robotics and automation.

- High Shock Load Capacity: The multiple points of contact between the cycloidal pins and the lobes distribute the load, allowing cycloidal gearboxes to handle sudden shocks and overloads effectively.

- Backlash Elimination: Cycloidal gearboxes exhibit minimal backlash due to the nature of their motion. This is beneficial in applications where precise motion reversal is crucial.

- High Efficiency: The rolling contact between the pins and lobes contributes to efficient power transmission, resulting in relatively high efficiency levels.

- Reduced Wear and Noise: The rolling motion in cycloidal gearboxes leads to reduced wear on components, resulting in lower maintenance requirements and quieter operation.

- Versatility: Cycloidal gearboxes can handle a wide range of ratios and speeds, making them suitable for various industrial and automation applications.

Due to these advantages, cycloidal gearboxes are commonly used in robotics, automation, packaging machinery, conveyors, and other applications where compactness, high torque, and precise motion are critical.

editor by CX 2024-05-09

China High Quality Gearbox for Tractor Pto manufacturer

Merchandise Description

OEM customized gearbox for agricultural equipment

1. Solution Description

| MODEL |

INPUT Knowledge | OUTPUT Data | |||||

| Ratio | Optimum Rpm | KW | HP-CV | N.M | N.M | R.P.M | |

| AC78845A/B | one:1.ninety three | 800 | thirty | 40 | 358 | 185 | 1544 |

| RC | 1:1.ninety three | 800 | thirty | forty | 358 | 185 | 1544 |

| RC5/BB60X | 1:1.69 | 800 | 37 | fifty | 440 | 260 | 1352 |

| AC78846A/B | 1:1.ninety three | 540 | fifty five | seventy five | 972 | 504 | 1042 |

| 612619 | one:1.93 | 540 | 74 | one hundred | 1308 | 678 | 1042 |

| 612666 | 1:1.46 | 540 | seventy four | a hundred | 1308 | 896 | 680 |

| BB84X | 1:1.26 | 540 | sixty seven | ninety | 1184 | 940 | 680 |

| RC81-000-01 | one:1.923 | 540 | 74 | 100 | 1308 | 680 | 1038 |

| RC81-000-02 | one:1.forty six | 540 | seventy four | a hundred | 1308 | 896 | 788 |

| 75356-192 | 1:1.92 | 540 | ninety seven | a hundred thirty | 1715 | 893 | 1037 |

| 75356-146 | one:1.forty six | 540 | 97 | one hundred thirty | 1715 | 1175 | 788 |

| 74823-19 | one:1.87 | 540 | ninety seven | one hundred thirty | 1715 | 918 | 1009 |

| 74823-14 | one:1.39 | 540 | ninety seven | a hundred thirty | 1715 | 1235 | 750 |

| GT40U.B | 3:1 | 540 | 44 | 60 | 778 | 2334 | 180 |

| SF-100 | one:1 | 540 | 15 | twenty | 265 | 265 | 540 |

| MCT-100A1 | seven.5:1 | 540 | 29.five | forty | 521 | 3912 | seventy two |

| MCT-100A2 | 22.5:1 | 540 | 29.5 | forty | 521 | 11738 | 24 |

| DCR1-0000 | 2.4:one | 540 | 37 | fifty | 654 | 1570 | 225 |

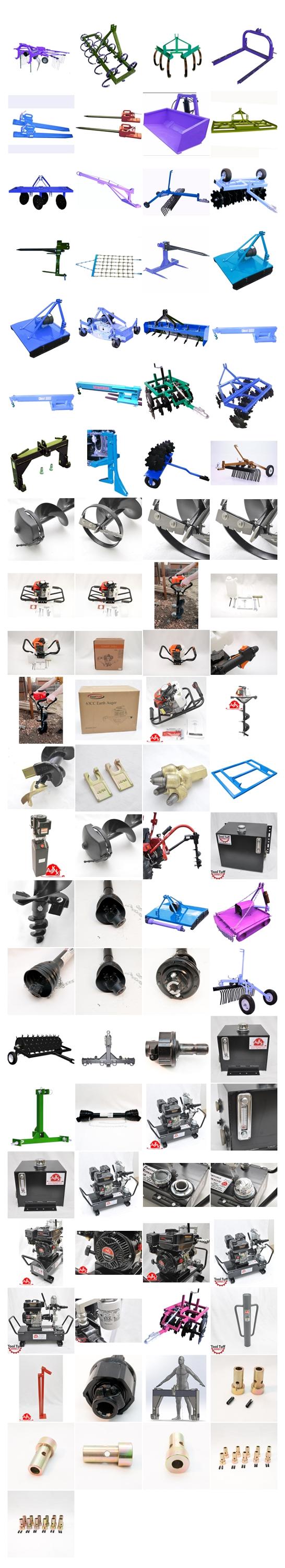

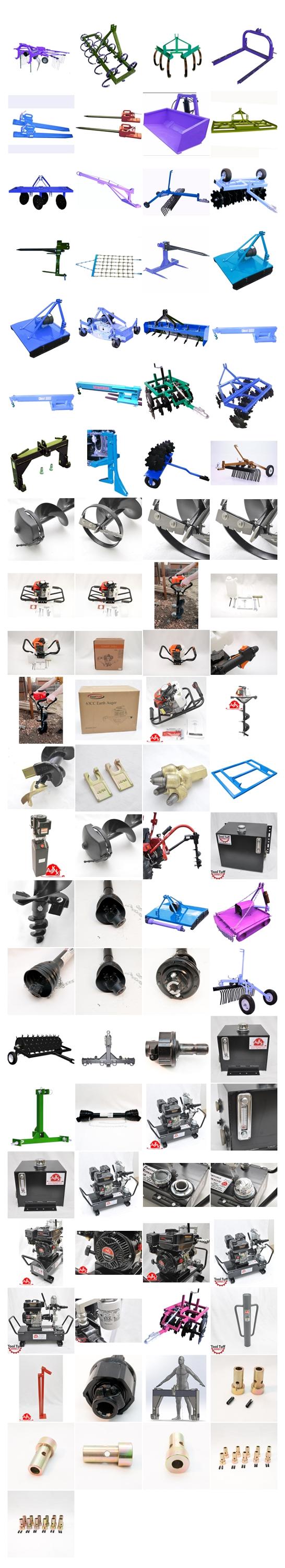

two. More Goods

3. The Drawing Of Equipment Box

four. Creation and Packing

five.Shipping and delivery

6.Our Organization

HangZhou CZPT Tech.Equipment Co.,Ltd was founded in 2003. It is situated at HangZhou County, HangZhou Metropolis, shut to 204 National Highway.Our main products: 1. all types of drive shaft 2.all sorts of gera box 3. Farm equipment: IMT500 inorganic fertilizer spreader, HMT05S organic fertilizer spreader, 3M rotovator , 3M damp-paddy subject rotary, King 185 deep cultviating machine and so on. 4.The machinery parts: several sorts of Gear, Shaft, Flang, ,Gear box, Laser elements, Stamping components and so on.

seven. FAQ

1. Q: Are your products cast or cast?

A: All of our items are forged.

two. Q: What is actually your MOQ?

A: twenty PCS for each sort. We accept the sample buy.

3. Q: What is the horse electrical power of the pto shaft are obtainable?

A: We supply a total range of pto shaft, ranging from 16HP-200HP.

4. Q: How several splined specification do you have ?

A: We produce 1 1/8″-Z6, 1 3/8″-Z6, 1 3/4″-Z6, 1 3/8″- Z21, 1 3/4″-Z20, 8X42X48X8 and 8X32X38X6 splines.

five. Q: How about the guarantee?

A: We promise 1 calendar year guarantee. With high quality problems, we will send you the new merchandise for free of charge within following cargo.

six. Q: What is actually your payment phrases?

A: T/T, L/C, D/A, D/P….

7. Q: What is the supply time?

A: 40 days soon after getting your superior deposit.

|

US $50-110 / Piece | |

30 Pieces (Min. Order) |

###

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Cycloidal |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Four-Step |

###

| Customization: |

Available

|

|---|

###

| MODEL |

INPUT DATA | OUTPUT DATA | |||||

| Ratio | Maximum Rpm | KW | HP-CV | N.M | N.M | R.P.M | |

| AC78845A/B | 1:1.93 | 800 | 30 | 40 | 358 | 185 | 1544 |

| RC | 1:1.93 | 800 | 30 | 40 | 358 | 185 | 1544 |

| RC5/BB60X | 1:1.69 | 800 | 37 | 50 | 440 | 260 | 1352 |

| AC78846A/B | 1:1.93 | 540 | 55 | 75 | 972 | 504 | 1042 |

| 612619 | 1:1.93 | 540 | 74 | 100 | 1308 | 678 | 1042 |

| 612666 | 1:1.46 | 540 | 74 | 100 | 1308 | 896 | 680 |

| BB84X | 1:1.26 | 540 | 67 | 90 | 1184 | 940 | 680 |

| RC81-000-01 | 1:1.923 | 540 | 74 | 100 | 1308 | 680 | 1038 |

| RC81-000-02 | 1:1.46 | 540 | 74 | 100 | 1308 | 896 | 788 |

| 75356-192 | 1:1.92 | 540 | 97 | 130 | 1715 | 893 | 1037 |

| 75356-146 | 1:1.46 | 540 | 97 | 130 | 1715 | 1175 | 788 |

| 74823-19 | 1:1.87 | 540 | 97 | 130 | 1715 | 918 | 1009 |

| 74823-14 | 1:1.39 | 540 | 97 | 130 | 1715 | 1235 | 750 |

| GT40U.B | 3:1 | 540 | 44 | 60 | 778 | 2334 | 180 |

| SF-100 | 1:1 | 540 | 15 | 20 | 265 | 265 | 540 |

| MCT-100A1 | 7.5:1 | 540 | 29.5 | 40 | 521 | 3912 | 72 |

| MCT-100A2 | 22.5:1 | 540 | 29.5 | 40 | 521 | 11738 | 24 |

| DCR1-0000 | 2.4:1 | 540 | 37 | 50 | 654 | 1570 | 225 |

|

US $50-110 / Piece | |

30 Pieces (Min. Order) |

###

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Cycloidal |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Four-Step |

###

| Customization: |

Available

|

|---|

###

| MODEL |

INPUT DATA | OUTPUT DATA | |||||

| Ratio | Maximum Rpm | KW | HP-CV | N.M | N.M | R.P.M | |

| AC78845A/B | 1:1.93 | 800 | 30 | 40 | 358 | 185 | 1544 |

| RC | 1:1.93 | 800 | 30 | 40 | 358 | 185 | 1544 |

| RC5/BB60X | 1:1.69 | 800 | 37 | 50 | 440 | 260 | 1352 |

| AC78846A/B | 1:1.93 | 540 | 55 | 75 | 972 | 504 | 1042 |

| 612619 | 1:1.93 | 540 | 74 | 100 | 1308 | 678 | 1042 |

| 612666 | 1:1.46 | 540 | 74 | 100 | 1308 | 896 | 680 |

| BB84X | 1:1.26 | 540 | 67 | 90 | 1184 | 940 | 680 |

| RC81-000-01 | 1:1.923 | 540 | 74 | 100 | 1308 | 680 | 1038 |

| RC81-000-02 | 1:1.46 | 540 | 74 | 100 | 1308 | 896 | 788 |

| 75356-192 | 1:1.92 | 540 | 97 | 130 | 1715 | 893 | 1037 |

| 75356-146 | 1:1.46 | 540 | 97 | 130 | 1715 | 1175 | 788 |

| 74823-19 | 1:1.87 | 540 | 97 | 130 | 1715 | 918 | 1009 |

| 74823-14 | 1:1.39 | 540 | 97 | 130 | 1715 | 1235 | 750 |

| GT40U.B | 3:1 | 540 | 44 | 60 | 778 | 2334 | 180 |

| SF-100 | 1:1 | 540 | 15 | 20 | 265 | 265 | 540 |

| MCT-100A1 | 7.5:1 | 540 | 29.5 | 40 | 521 | 3912 | 72 |

| MCT-100A2 | 22.5:1 | 540 | 29.5 | 40 | 521 | 11738 | 24 |

| DCR1-0000 | 2.4:1 | 540 | 37 | 50 | 654 | 1570 | 225 |

How to Use a Cyclone Gearbox

Often, a cycloidal gearbox is used in order to achieve a torque transfer from a motor or pump. This type of gearbox is often a common choice as it has a number of advantages over a regular gearbox. Its main advantage is that it is easy to make, which means that it can be incorporated into a variety of applications. However, if you want to use a cycloidal gearbox, there are a few things that you need to know. These include the operation principle, the structure and the dynamic and inertial effects that come with it.

Dynamic and inertial effects

Several studies have been carried out on the static and dynamic properties of cycloidal gears. The study of these effects is beneficial in assisting optimal design of cycloidal speed reducers.

In this paper, the dynamic and inertial effects of a two-stage cycloidal speed reducer have been investigated using the CZPT program package. Moreover, a new model for cycloidal reducers based on non-linear contact dynamics has been developed. The new model aims to predict several operational conditions.

The normal excitation contact force for the cycloid discs of the first and second stage is very similar. However, the total deformation at the contact point is different. This effect is mainly due to the system’s own oscillations. The cycloid discs of the second stage turn around the ring gear roller with a 180deg angle. This angle is a significant contributor to the torque loads. The total excitation force on the cycloid discs of first and second stage is 1848 N and 2068.7 N, respectively.

In order to analyze the contact stress, different gear profiles were investigated. The mesh density was considered as an important design criterion. It was found that a bigger hole reduces the material content of the cycloidal disc and results in more stresses.

Moreover, it is possible to reduce the contact forces in a more efficient manner by changing the geometric parameters. This can be done by mesh refinement along the disc width. The cycloidal disc has the greatest influence on the output results.

The efficiency of a cycloidal drive increases with the increase in load. The efficiency of a cycloidal reducer also depends on the eccentricity of the input shaft and the cycloidal plate. The efficiency curve for small loads is linear. However, for the larger loads, the efficiency curve becomes more non-linear. This is because the stiffness of the cycloid reducer increases as the load increases.

Structure

Despite the fact that it looks like a complicated engineering puzzle, the construction of a cycloidal gearbox is actually quite simple. The key elements are the base, the load plate and the thrust bearing. All these elements work together to create a stable, compact gearbox.

The base is a circular section with several cylindrical pins around its outer edge. The pins are fixed on a fixed ring that holds them in a circular path. The ring serves as a reference circle. The circle’s size is approximately 5mm in diameter.

The load plate is a series of threaded screw holes. These are arranged 15mm away from the center. These are used to anchor external structures. The load plate must be rotated around the X and Y axis.

The thrust bearing is placed on top of the load plate. The bearing is made of an internal diameter of 35mm and an external diameter of 52mm. It is used to allow rotation around the Z axis.

The cycloidal disc is the centerpiece of the cycloidal gearbox. The disc has holes for the pins that drive the output shaft. The holes are larger than those used in output roller pins. The disc also has a reduced eccentricity.

The pins are attached to the cycloidal disc by rolling pins. The pins are made of a material that provides mechanical support for the drive during high-torque situations. The pins have a 9mm external diameter. The disc has a number of lobes and is rotated by one lobe per shaft revolution.

The cycloidal gearbox also has a top cover that helps keep the components together. The cover has a pocket for tools. The top cover also has threads that screw into the casing.

Operation principle

Among many types of gear transmissions, cycloidal gearboxes are used in heavy machinery and multi-axis robots. They are highly effective, compact and capable of high ratios. In addition, they have an overload capability.

Cycloid disks are driven by eccentric shafts that rotate around fixed ring pins. Roller pins of the pin disc engage with holes in the cycloidal disc. These roller pins drive the pin disc and the pin disc transfers the motion to the output shaft.

Unlike conventional gear drives, cycloidal drives have low backlash and high torsional stiffness. They are ideally suited to heavy loads and all drive technologies. The lower mass and compact design of the cycloidal disk also contributes to its high efficiency and positioning accuracy.

The cycloidal disc plays a central role in the gearbox kinematics. It rotates around a fixed ring in a circle. When the disc is pushed against the ring gear, the pins engage with the disc and the roller pins rotate around the pins. This rotating motion generates vibration, which travels through the driven shafts.

Cycloid discs are typically designed with a short cycloid, so that the eccentricity is minimized. This reduces unbalance forces at high speeds. Ideally, the number of lobes on the cycloid is smaller than the number of surrounding pins. This reduces the amount of Hertzian contact stress.

Unlike planetary gears, cycloidal gears have high accuracy and are capable of withstanding shock loads. They also experience low friction and less wear on tooth flanks. They also have higher efficiency and load capacity.

Cycloid gears are generally more difficult to manufacture than involute gears. Cycloid gears are not suitable for stacking gear stages. They require extreme accuracy for manufacturing. However, their smaller size and low backlash, high torsional stiffness, and low vibration make them ideal for use in heavy machines.

Involute gear tooth profile

Almost all gears are manufactured with an involute gear tooth profile. Cycloid gears are also produced with this profile. Compared with involute gears, cycloid gears are stronger and can transmit more power. However, they can also be more difficult to manufacture. This makes them costlier.

The involute gear tooth profile is a smooth curve. It is derived from the involute curve of a circle. A tangent to the base circle is the normal at any point of an involute.

This curve has properties that allow the involute gear teeth to transfer motion in perpendicular direction. It is also the path traced by the end of the string unwrapping from a cylinder.

An involute profile has the advantage of being easy to manufacture. It also allows for smooth meshing despite misalignment of the centre distance. This profile is also preferred over a cycloid tooth profile, but it is not the best in every regard.

Cycloid gear teeth are also made of two curves. Unlike involute teeth, cycloid gear teeth have a consistent radius. Cycloid gears are less likely to produce noise. But they are also more expensive to manufacture.

Involute teeth are easier to manufacture because they have only one curve. Cycloid gears can also be made with a rack type cutter. This makes them cheaper to manufacture. However, they require an expert design. They can also be manufactured with a gear shaper that includes a pinion cutter.

The tooth profiles that satisfy the law of gear-tooth action are sometimes called conjugate profiles. The involute profile is the most common of these. It allows for constant torque transmission.

Backlash

Typically, cycloidal drives provide a high ratio of transmission with no backlash. This is because the cycloid disc is driven by an eccentric shaft. During rotation, the cycloid disc rotates around a fixed ring. This ring also rotates independently of the center of gravity.

The cycloid disc is typically shortened to reduce the eccentricity. This helps to minimize the unbalance forces that may occur at high speeds. The cycloid also offers a larger gear ratio than traditional gears. This provides a better positional accuracy.

Cycloid drives also have a high torsional stiffness. This provides greater torsional resilience and shock load capabilities. This is important for a number of reasons, such as in heavy-duty applications.

Cycloid drives also have lower mass. These benefits make them ideally suited for all drive technologies. The design also allows for higher torsional stiffness and service life. These drives also have a much smaller profile.

Cycloid drives are also used to reduce speed. Because of the high torsional stiffness of the cycloid, they also have high positioning accuracy.

Cycloid drives are well-suited to a variety of applications, including electric motors, generators, and pump motors. They are also highly resistant to shock loads, which is important in a variety of applications. This design is ideal for applications that require a large transmission ratio in a compact design.

Cycloid drives also have the advantage of minimizing the clearance between the mating components. This helps to eliminate interference and ensure a positive fit. This is particularly important in gearboxes. It also allows for the use of a load cell and potentiometer to determine the backlash of the gearbox.

editor by czh 2023-01-21

China manufacturer & factory supplier for Agricultural in Thrissur India machine parts 4ft 5ft 6ft 7ft 3 Point Heavy Disc Plow Tractor Plough With high quality best price & service

Our business has strong financial strength, builds up a technician crew contingent with substantial top quality, possesses the creation assembly line of technicalization in China and excellent method checking on merchandise high quality and operates marketing and advertising networks all through the region.

Maker of standard and custom roller chains. Suited for ageing, anxiety relieving, warmth dealing with and powder coating purposes. Aerospace, automotive, armed forces, power, composite, pharmaceutical and different other industries served. Turnkey programs integration and most products available in inventory.Innovative thermo tHow Can You Be Risk-free When Employing PTO Shafts? First, make positive the shaft is shielded. This involves the driveline defend that handles the employ driveline, and the grasp shield which addresses the common joint and PTO stub shaft on the tractor.Maintain the shield so it can function for you. PTO driveline shields are normally mounted on bearings, so they require to be preserved. always REPLACE the defend when it is ruined or missing.Up coming, hold a secure length from it when in use. Maintain other people away, also. How far? A length of 2 times your top is a very good begin.Allow only people who absolutely have to be in the spot to be there. Maintain all kids absent!Always shell out focus to what is occurring. Most PTO victims were caught by shock.If some thing goes improper — quit the machinery get the PTO out of equipment, cease the engine and established the brake. Place the keys in your pocket just before doing work on the equipment.When halting the equipment for any purpose — finish of function, lunch, repairs, or interaction — consider the PTO out of equipment, end the engine and established the brake.Road planers, dredges, and other products require energy from some kind of engine in buy to perform their developed purpose. Without a electricity get off, it would be necessary to add a 2nd motor to provide the electrical power necessary to run hydraulic pumps and other driveline attached equipment.reatment products, such as community heat treatment oven, multi-use thermo therapy oven, and so forth.

Overview

Quick Specifics

- Situation:

-

New

- Sort:

-

Farm Cultivator

- Certification:

-

CE

- Warranty:

-

one 12 months

- After-revenue Provider Provided:

-

Online assist

- Use:

-

farm products

- Area of Origin:Zhejiang, China

- Brand Title:

-

OEM

- Weight:

-

240KG

- Dimension(L*W*H):

-

one hundred thirty*a hundred and twenty*80cm

- Crucial Selling Factors:

-

Substantial Efficiency

- Marketing and advertising Kind:

-

Regular Product

- Machinery Test Report:

-

Offered

- Movie outgoing-inspection:

-

Supplied

- Guarantee of core components:

-

1 Year

- Main Factors:

-

OEM

- Right after Guarantee Support:

-

Video specialized support, On the web support

- Applicable Industries:

-

Farms, OEM

- Local Service Location:

-

None

- Showroom Place:

-

United States, None

- Local Support Location:

-

United States

- Color:

-

Optional

- Working Width:

-

one.2m 1.5m 1.8m

- Tractor HP:

-

25-55HP

- Operating depth:

-

20cm

- disc measurement:

-

16 inch

- Model:

-

weighty responsibility

- Other Country:

-

CHINA

Offer Ability

- Offer Potential:

- a hundred Piece/Parts for every Week

Packaging & Supply

- Packaging Information

- Metal Crate

- Port

- NINGBO OR SHANGHAI

-

Direct Time

: -

Amount(Parts) one – a hundred >100 Est. Time(days) 35 To be negotiated

On the web Customization

Product Data

Item Description

At Hangzhou Ever-Power Agricultural Equipment Co.Ltd we are specialist in top quality agri-parts like agricultural gearboxes, pto shafts, 3 details tractor attachments and skid steer and forklift implements at very competitive prices. Our selection of implements involves PTO shafts, gearboxes for agricultural equipment, post gap digger, auger, tractor slashers, grader blades, spear , box scrapers,, ATV implements, agri- rippers, hydaulic cylinders, Telescopic Fork Mounted Jibs, Basic safety Cage etc. We have far more than 30 a long time production expertise.

| Relevant Industries | Farms |

| Condition | New |

| Certification | CE |

| Guarantee | 1 12 months |

| Soon after-revenue Provider Offered | Free spare components,Discipline maintenance and mend services,Online video complex assist,On the internet support |

| Use | farm products |

| Location of Origin | China |

| Manufacturer Title | EP |

| Excess weight | 240KG |

| Dimension(L*W*H) | 130*120*80cm |

| China | Zhejiang |

| Colour | Optional |

| Working Width | 1.2m 1.5m 1.8m |

| Tractor HP | twenty five-55HP |

| Doing work depth | 20cm |

| disc dimension | 16 inch |

| Model | heavy obligation |

| Other Nation | CHINA |

Item Exhibit

Item Screen

faq

Best China manufacturer & factory agricultural in Oklahoma City United States machinery parts transmission cardan tractor clutch spline driveline shaft With high quality best price

The product properly displays environmental safety and power preserving.

Overview

Quick Details

- Guarantee:

-

one.5 a long time

- Relevant Industries:

-

Manufacturing Plant

- Following Guarantee Service:

-

On-line assistance

- Nearby Service Location:

-

None

- Showroom Location:

-

Italy

- Kind:

-

Shafts

- Use:

-

Tractors

- Place of Origin:Zhejiang, China

- Brand Identify:

-

OEM

- Neighborhood Service Location:

-

Italy

- certificate:

-

CE

- Material:

-

Metal

- plastic guard:

-

YWBSYSBW tractor pto shaft

- purpose:

-

transmit power tractor pto shaft

- spline:

-

1 3/8 Z6/Z21 tractor pto shaft

Supply Capacity

- Supply Capability:

- ten thousand Piece/Pieces for every Month tractor pto shaft

Packaging & Shipping and delivery

- Packaging Particulars

- carton/iron crate tractor pto shaft

- Port

- ningbo or shanghai

Online Customization

Item Details

Merchandise Information

PTO Shaft

The power consider-off (PTO) is a refined system, enabling implements to attract strength from the engine and transmit it to yet another application. It performs as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The energy take-off shaft (PTO shaft) is a essential ingredient, made and manufactured for steady weighty-responsibility use. A great PTO shaft should be powerful sufficient to bear the torsion and shear stress and miniSHAFT Surface area High quality To purpose successfully and supply satisfactory lifestyle, oil seals must have a skinny oil film in between the seal lip and mating shaft journal. This condition, recognized as hydrodynamic lubrication, wants shaft surfaces that are not perfectly smooth but have microscopic pockets to support keep the lubricant film.–Driven (outer) yoke very same as generate yoke but is mounted on the employ. There are two varieties of shafts, domestic and metric, which are identifiable by their designs. Domestic are typically a single of 4 designs: spherical, sq., rectangle or splined. Metric are: bell, star or soccer formed. In both situation the main (entrance) shaft is the very same form as the secondary shaft, only even bigger so that the secondary shaft suits inside of. This permits a telescoping influence to get location when the employ is elevated on the 3 pt. or for the duration of a turning movement this sort of as a bailer. All shafts have to be sized ahead of use. Attach the implement to the 3 pt. and raise and support it. Attach the suitable conclude to the tractor and attempt to attach the other to the employ. If the shaft is way too lengthy trim 1 of the shafts with a hack observed and try it once more until finally it fits. This makes it possible for for the implement to be raised with no binding. The shafts need to overlap as much as authorized. Though plunge grinding is most widely employed to end seal journals, the resulting area is not best from this standpoint. Other ending approaches, this kind of as shot peening and liquid honing, provide a matte-variety finish which is usually more successful than a plungeground floor. Nonetheless, even these approaches typically leave raised, sharp corners that individual the ensuing microscopic indentations, yet again providing potential starting details for leaks.mize vibration.

Setforge, the forging subsidiary of Ever-Energy Group, manufactures chilly extruded PTO shafts for all types of agriculture cars. Our PTO shafts supply great dependability and longevity for the duration of every day use.

EP Group has been internationally recOur goods are marketing properly in Chinese marketplaces and some merchandise offered in worldwide marketplaces are properly gained by Chinese and foreign clientele at residence and overseas.ognized as a reliable world-wide supplier. Our condition-of-the-artwork producing approach and seasoned engineers ensure the top-top quality of all Farinia parts.

| Right after Guarantee Provider | Video clip technical support |

| Applicable Industries | Producing Plant |

| Local Support Spot | Italy |

| Showroom Area | Italy |

| Warranty | 1.5 a long time |

| Sort | Shafts |

| Use | Tractors |

| Area of Origin | China |

| China | Zhejiang |

| Brand name Title | EPG |

| certification | CE |

| Material | Metallic |

| plastic guard | YWBSYSBW tractor pto shaft |

| purpose | transmit electrical power tractor pto shaft |

| spline | 1 3/8 Z6/Z21 tractor pto shaft |

Product Show

Merchandise Screen

CAT 2 High definition Rapid Hit …

fifteen” Hefty Obligation Ear …

Agricultural Machi …

CompanyInfo

Company Profile

Ever-Power Team

EPG have large-tech machinery and take a look at products. We can generate entire world class substantial precision merchandise.

Certifications

Certifications

Cargo & Payment

Our Positive aspects

A: Your inquiry related to our goods or rates will be replied in 24 hours.

B: Security of your sales location, ideas of design and style and all your private info.

C: Best good quality and competitive price tag.

……

faq

FAQ

1) How can I location purchase?

A: You can get in touch with us by e mail about your get information, or location order on line.

2) How can I pay out you?

A: After you validate our PI, we will request you to pay. T/T (HSBC financial institution) and Paypal, Western Union are the most typical techniques we are making use of.

……